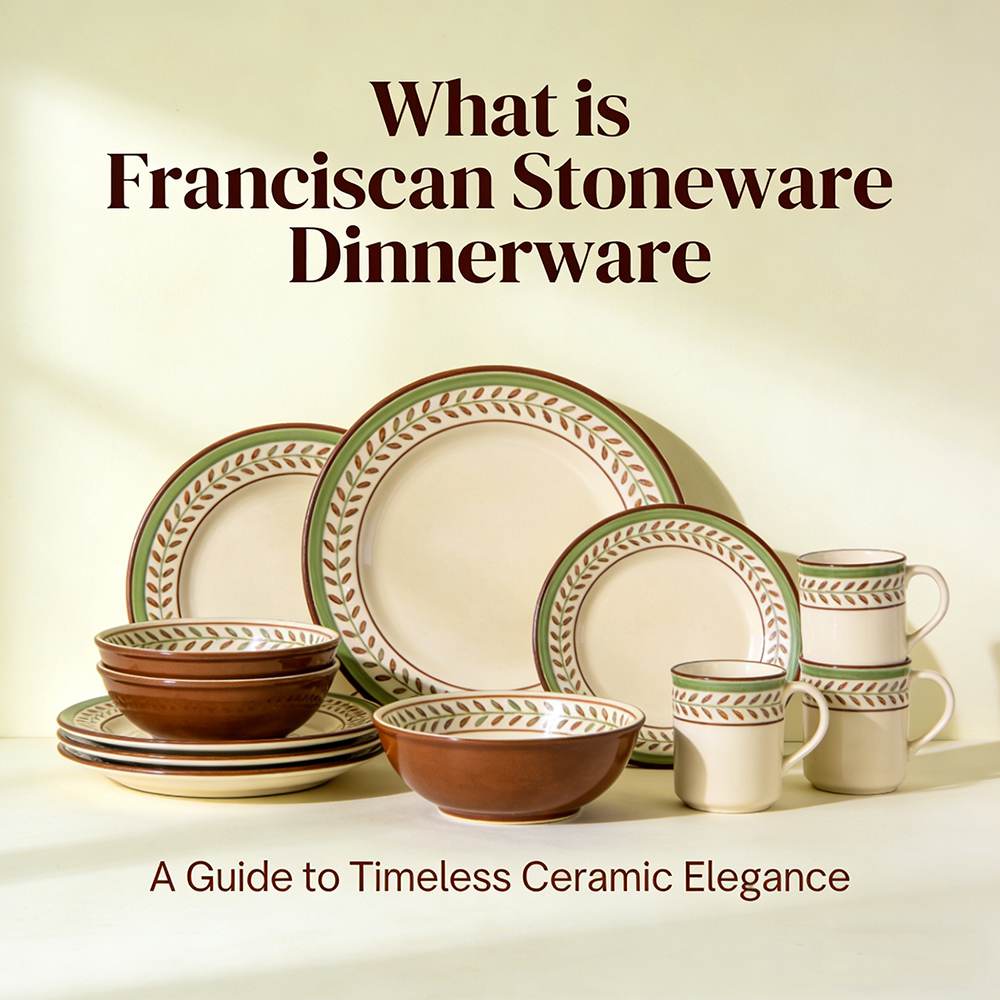

Dinnerware isn’t just a functional necessity; it’s an integral part of creating memorable dining experiences. From fine porcelain to rustic stoneware, different materials offer unique aesthetics and qualities. Among these, Franciscan Stoneware Dinnerware stands out as a beloved classic. Known for its durability, timeless design, and distinctive craftsmanship, Franciscan stoneware has made its mark as one of the most recognizable dinnerware brands in the United States. In this article, we’ll explore what Franciscan stoneware dinnerware is, its history, features, and why it remains a popular choice for collectors and everyday use alike. What Is Franciscan Stoneware? Franciscan stoneware refers to the dinnerware line produced by Franciscan Pottery, an American ceramics manufacturer founded in 1934. The company is known for crafting high-quality stoneware and pottery, with dinnerware sets that became particularly popular in the mid-20th century. Over the years, Franciscan stoneware has come to symbolize both functionality and elegance in American homes. Unlike fine china, which is made from porcelain, stoneware is crafted from clay and fired at a high temperature, making it denser, thicker, and more durable. Franciscan stoneware, in particular, often features beautiful, intricate designs, and is made to be used for both everyday dining and special occasions. The History of Franciscan Stoneware Dinnerware Franciscan Pottery was founded by Frederick Hurten Rhead, an English-born designer, who introduced a range of stoneware pieces for the American market. The brand quickly gained recognition for its combination of innovative designs and durable craftsmanship. In 1934, Franciscan pottery began producing stoneware dinnerware sets that became known for their beauty and practicality. Throughout the years, Franciscan Pottery evolved, with designs shifting in line with various cultural and aesthetic movements, such as Art Deco, Mid-Century Modern, and Retro designs. The company was especially known for creating intricate hand-painted patterns and vibrant glazes, which helped to establish the popularity of Franciscan stoneware across American homes, as well as overseas. In the 1950s, one of the most iconic patterns, “Franciscan Desert Rose”, was introduced. This pattern featured delicate pink roses on a muted cream-colored base, and it became an instant classic. For many, Franciscan Desert Rose remains the brand’s most recognizable design. By the late 1980s, Franciscan Pottery was acquired by Wedgewood, which is now part of the Waterford Wedgwood group, but the legacy of the brand continues to influence stoneware design to this day. Key Features of Franciscan Stoneware Dinnerware 1. Durability One of the defining characteristics of Franciscan stoneware is its durability. Stoneware is known for being thick and strong, making it a practical choice for daily use. The high firing temperatures at which the stoneware is baked contribute to its strength and chip resistance, making it an ideal material for both casual and formal dining. 2. Distinctive Designs Franciscan Pottery was famous for its innovative and varied patterns, which set the brand apart from other dinnerware makers. From the delicate florals of Desert Rose to the rustic Ivy pattern, Franciscan stoneware often featured hand-painted designs or beautifully glazed finishes. These vibrant colors and artistic patterns made the brand’s dinnerware a standout in homes and restaurants. 3. Versatility Franciscan stoneware is known for its ability to transition from everyday dining to special occasions with ease. Whether hosting a casual dinner or a formal gathering, Franciscan pieces bring a level of elegance and charm to any table setting. The stoneware is also microwave-safe and dishwasher-safe, adding to its practicality for modern-day dining. 4. Heirloom Quality Many collectors of Franciscan dinnerware appreciate its heirloom quality. Due to the timeless designs and durable material, Franciscan pieces often become cherished family heirlooms. Many people find that the pieces retain their beauty and function for generations, which contributes to their lasting popularity. Popular Patterns and Designs of Franciscan Stoneware Franciscan Desert Rose Undoubtedly the most famous pattern of Franciscan dinnerware, Desert Rose was first introduced in 1941. Featuring soft pink roses set against a warm cream-colored background, this design exudes a vintage charm that has made it a favorite among collectors. Desert Rose continues to be highly sought after, especially for those seeking to complete or expand their collection of Franciscan dinnerware. Franciscan Ivy The Ivy pattern is another signature design from Franciscan, characterized by green ivy leaves against a white or cream background. This elegant and nature-inspired design offers a more understated alternative to the floral motifs, and its simplicity makes it versatile enough to be paired with various other dinnerware collections. Franciscan Apple Apple is a charming, playful pattern that features vibrant red apples set against a soft cream-colored background. It captures the essence of home cooking and comfort, making it an ideal choice for casual dining or country-themed décor. Franciscan Monterey The Monterey pattern stands out with its vibrant blue, orange, and yellow hues. This design evokes a more retro vibe, reminiscent of mid-century modern aesthetics. It is bold and colorful, making it an excellent choice for those looking to add a touch of excitement to their table settings. Why Franciscan Stoneware is Still Popular Today Even though Franciscan Pottery ceased production decades ago, its stoneware continues to be beloved for several reasons: Timeless Beauty: The intricate designs and craftsmanship of Franciscan stoneware have never gone out of style. Whether it’s the vintage charm of Desert Roseor the sleek elegance of Ivy, these patterns still fit perfectly in contemporary settings, providing a beautiful contrast to today’s minimalist trends. Collectibility: Franciscan dinnerwareis highly collectible, with many sets and individual pieces still being sold on the second-hand market. Whether bought for its value or nostalgia, collectors continue to seek out rare pieces, ensuring the brand’s legacy. Durability and Practicality: Despite being a vintage brand, Franciscan stoneware is known for its durability and functionality, making it a great option for both practical everyday use and special occasions. Vintage Appeal: For those who love vintage décor, Franciscan dinnerwareoffers an opportunity to own a piece of history, connecting the modern world to the mid-century era. Conclusion Franciscan stoneware dinnerware is a symbol of American craftsmanship and timeless design. Its rich history, exceptional durability, and iconic patterns have made it a favorite among collectors and everyday users alike. Whether you are looking for the charming Desert Rose, the understated elegance of Ivy,

Stainless Steel Flatware Grades Explained: 18/10 vs 18/0 (Cost vs Lifespan Comparison)

Stainless steel flatware comes in different quality levels, and the numbers on the box, like 18/10 or 18/0, actually tell you what you’re buying. Those grades refer to the mix of chromium and nickel inside the steel, and that mix affects flatware durability, shine, and how long it holds up in daily service. If you’re comparing 18/10 flatware vs 18/0, the decision usually comes down to one thing: do you want a lower upfront price, or a longer flatware lifespan with fewer replacement cycles? In this guide, we’ll break down stainless steel grades, performance, and a simple cost comparison so your hospitality procurement choice feels easy. What’s the Difference Between 18/10 Flatware vs 18/0? When you’re buying flatware for a restaurant, hotel, or catering setup, these stainless steel grades tell you what the steel is made of, and that directly affects how your flatware looks after months of dishwashing, heavy service, and constant handling. So if you’re stuck choosing between 18/10 vs 18/0 flatware, this section breaks it down. 18/10 Stainless Steel Flatware 18/10 flatware is stainless steel flatware made with 18% chromium and 10% nickel. That nickel is the reason it’s considered the premium option in hospitality. It helps the flatware stay shinier, resist rust spots, and hold up better through heavy dishwashing and daily service use. This is the type of flatware you pick when you want your cutlery to still look sharp after a long season of service, not just on day one. 18/0 Stainless Steel Flatware 18/0 flatware is stainless steel flatware made with 18% chromium and 0% nickel. It’s usually the budget-friendly option because it skips the nickel, which keeps the cost down. The trade-off is that it can lose its shine faster over time and may show more spotting or surface wear in busy commercial kitchens. How 18/10 and 18/0 Stainless Steel Grades Are Named The format for stainless steel grades is simple: X/Y. The first number is the chromium percentage, and the second number is the nickel percentage. So when you see 18/10, that means the flatware contains around 18% chromium and 10% nickel. And 18/0 means around 18% chromium and 0% nickel. Now you might ask, why does this matter? Because those two metals decide how your flatware holds up once it’s been through hundreds of wash cycles, gets tossed into bus tubs, and gets handled by multiple staff members in one night. What Chromium Does (The “18” Part) Chromium is what gives stainless steel its basic rust resistance. It forms a protective layer on the surface, so the steel doesn’t break down easily when it’s exposed to water, heat, and daily washing. That’s why both 18/10 and 18/0 can still qualify as “stainless,” because both rely on chromium for that base protection. So even if you choose 18/0 flatware, you’re not choosing something low-quality by default. You’re choosing a grade that’s built for value, with fewer extras. What Nickel Changes (The “10” vs “0” Part) Nickel helps flatware keep that cleaner shine longer, and it improves resistance to spotting, surface wear, and corrosion marks that can show up when cutlery goes through heavy service routines. It also changes the feel in the hand. If you’ve ever picked up cutlery and thought, “Yeah, this feels premium,” nickel is usually part of that story. The reason 18/10 costs more is simple: nickel isn’t cheap, and adding it changes both performance and price. Why You’ll Also See 18/8 (And Why It Confuses Buyers) If you’ve been shopping for stainless steel grades, you’ve probably noticed 18/8 sitting right beside 18/10. Here’s the short version: in most commercial cases, 18/8 and 18/10 perform very similarly, and the difference is rarely something you’ll feel during service. A lot of suppliers buy steel that falls within a range, then label it based on what sells best. Some call it 18/10. Some call it 18/8. The British Stainless Steel Association even notes that 18/10 is sometimes used as an alternative label to 18/8, and in practice, it can be more marketing than a true upgrade. So treat them as the same tier and compare quality, pros, and cons instead. Take a look at the pros and cons of stainless steel flatware grades. Grade Pros Cons 18/10 Stainless Steel Flatware l Strong rust and corrosion resistance in commercial dishwashing l Holds its shine and polish for longer l Better resistance to staining, spotting, and pitting l Feels more premium in weight and finish l Long-term durability makes it ideal for daily service l Not magnetic (can matter for some recovery systems) l Not always necessary for casual or short-term setups l Higher upfront cost compared to 18/0 18/0 Stainless Steel Flatware l Lower cost upfront (budget-friendly for bulk buying) l Magnetic (easier to recover in dishwashing/trash systems) l Works fine for casual service and lower-expectation settings l Good corrosion resistance for the price (still stainless steel) l More likely to lose shine faster over time l Can show spotting, staining, or dulling sooner l Less resistant to harsh washing conditions and acidic residue l May need more frequent replacement in high-volume venues Performance Comparison: How Stainless Steel Grades Differ in Practice Both stainless steel grades look great when they’re brand new. The difference shows up after weeks of dishwashing, busy shifts, and constant contact with food, water, and heat. If you’re choosing based on flatware durability and flatware lifespan, this is the part that makes the decision clear. Durability and Lifespan In a restaurant, hotel, or catering business, flatware gets tossed in bus tubs, soaked, washed on high heat, and used the same day. That’s where 18/10 stainless steel usually performs better. It stays cleaner and brighter longer and holds up better when your menu includes acidic foods like lemon, vinegar, or tomato sauce. This is why flatware lifespan can look completely different between stainless steel grades, even when both sets start out looking the same. 18/0 flatware still works, but in heavy service, it can start looking dull or spotty sooner, especially with hot dishwashing, hard water, or wet storage. The Visual Aging Story At

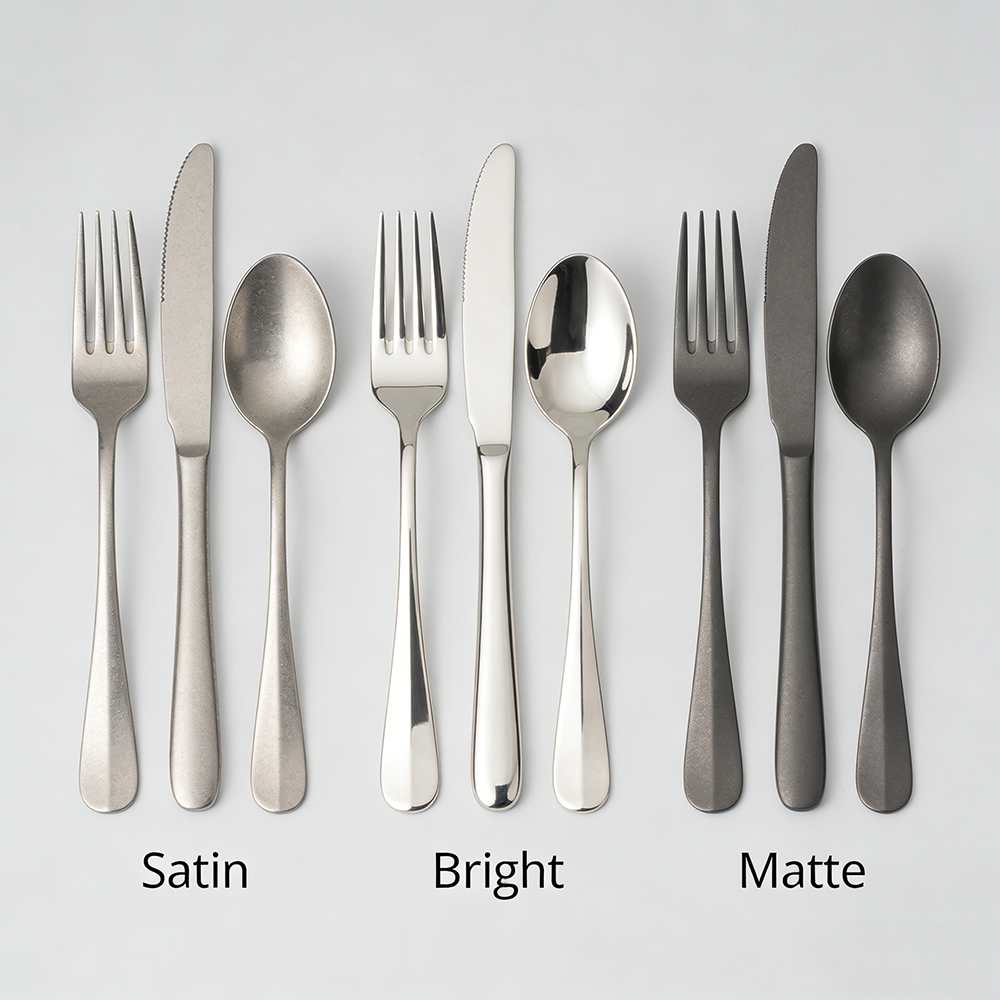

Commercial Flatware Finishes: Satin, Bright, and Matte (Aesthetic, Maintenance, and Cost)

Flatware finishes can change the entire vibe of your table, even when the pattern stays the same. You’re holding the exact same fork in three versions. One is a mirror polish that reflects the ceiling lights like a spotlight. One is a satin finish with a soft, brushed glow. And one is matte flatware that looks modern and clean. Same steel, same shape, but totally different look. Here’s the part most buyers learn after the purchase: the finish you pick doesn’t just affect the look. It affects flatware maintenance, staff time, and how your flatware holds up after months of dishwashing and daily service. Let’s explore the different types of commercial flatware finishes and how they perform in service. What Are the Main Flatware Finishes in Restaurants and Hotels? Flatware finishes influence how your cutlery looks under lighting, how fast it shows wear, and how much effort it takes to keep it looking clean between services. Here’s a simple breakdown. Mirror Polish Flatware (Bright Finish) Mirror polish is the classic ‘shiny silver’ look. It’s made by buffing the surface until it becomes smooth and reflective, like a mini mirror on the table. This finish makes flatware look more formal and high-end, which is why it’s common in fine dining, luxury hotels, and weddings. Satin Finish Flatware (Brushed Finish) A satin finish (also called a brushed finish) has a soft shine, not a full reflection. It’s created using brushing or abrasion techniques that leave a subtle texture on the surface. This is the best-of-both-worlds finish for most venues because it looks premium without demanding constant attention. It hides fingerprints better than mirror polish, holds its look longer in busy service, and works across modern, classic, and upscale concepts without clashing with your dinnerware. Matte Flatware (Modern Finish) Matte flatware is the low-shine, modern finish that gives a contemporary look. It absorbs light instead of reflecting it, so it does not sparkle like mirror polish or glow like satin. This finish is popular in trendy restaurants, cafes, high-volume venues, and catering kits because it hides wear extremely well and needs very little visual upkeep. If your flatware goes through nonstop wash cycles, matte usually stays good enough without requiring extra work. Aesthetic Impact: How Flatware Finish Changes the Dining Experience Flatware finishes do more than change a fork’s look. They change the message your table sends before the food even lands. So if you’re deciding on a hotel, restaurant, or catering program, this is really a brand choice, not just a style preference. Mirror Polish: The Formal Statemen Mirror polish is the finish that makes a formal statement. Light bounces off it, candles reflect in it, and the table instantly feels more elevated. Guests usually read polished flatware as “high standards,” especially in luxury hotels, fine dining, and formal events, where the goal is to make everything feel intentional. But that same shine that looks premium can also feel a little too serious in a casual concept. A bright finish in a busy brunch spot can look out of place, like it’s trying too hard. So in this case, you normally expect mirror polish to be the best, but it only works when the entire setup supports it. If your dining room is built for elegance, mirror polish creates the celebratory look design pros talk about. Satin Finish: The Safe Choice That Still Looks Premium A satin finish is what you choose when you want the table to look expensive without putting on a show. The surface has a soft glow instead of a full reflection, which makes it feel modern. Restaurant operators love it because it fits almost anywhere: boutique hotels, upscale casual, modern dining rooms, and even corporate catering, where everything needs to look clean and consistent. Honestly, satin saves you from design regret. You can pair it with porcelain dinnerware, stoneware, wood boards, darker plates, and lighter plates, and it rarely clashes. In other words, if you want quality without the “spotlight effect,” a satin finish strikes a balance between polish and practicality. Matte Finish: The Modern, Minimal Look Matte finish is what you pick when the concept is clean, current, and not trying to look traditional. The finish stays low-shine, so the table feels more relaxed, more design-forward, and less formal. You’ll see it in farm-to-table restaurants, wellness cafes, modern casual spots, and venues with darker dinnerware or textured plating. So in this case, you’d normally expect matte to feel too casual, but that’s not always true. In the right concept, it feels intentional. Matte is also a strong fit for venues that want a modern, minimal table aesthetic without extra shine. How the Finish Works With Your Dinnerware Mirror polish stands out the most, so it works best with classic or dramatic table settings where you want contrast and sparkle. Satin finish blends easily and supports almost any dinnerware style without taking over. Matte flatware pairs best with minimalist plates, darker tones, modern shapes, and textured ceramics, where the goal is harmony. Which Flatware Finish Is Easiest to Maintain? Flatware finishes do not just change how your table looks. They change how much time your team spends wiping, drying, polishing, and “fixing the shine” before service. Mirror polish looks stunning, but it shows fingerprints and water spots immediately, so staff usually end up hand-drying and touching it up more than they planned. To keep it looking pristine, most venues end up stocking microfiber cloths, stainless steel-safe polish, and soft buffing towels, and they usually have someone assigned to do quick touch-ups before service. Satin finish still looks elevated, but the brushed surface hides smudges, so normal dishwashing is usually enough. Matte flatware is the lowest-effort option because it hides water spots, fingerprints, and light scratches so well, making it easier for high-volume venues to keep service looking clean without extra steps. Maintenance comparison by finish: Mirror polish: Highest upkeep, most polishing, and hand-drying Satin finish:Moderate upkeep, hides marks well Matte flatware: Lowest upkeep, the easiest to

Commercial Flatware Selection Guide: Materials, Weights, and Durability for Restaurants

Commercial flatware selection sounds simple until you start tracking replacements and realize some sets cost less upfront but create more work and spend over time. Some bend more easily during heavy use. Others lose their shine sooner. Only a few hold up through years of dishwashing and handling. For hotel procurement managers and restaurant teams, which stainless steel grade and weight will match your concept and still last in daily service is a practical question. This guide breaks down commercial flatware, including stainless steel flatware grades, weight, and durability. You will also learn how to choose the right set for your restaurant so your hospitality tableware stays consistent across service and reorders. Stainless Steel Flatware Grades: 18/10 vs 18/8 vs 18/0 After you notice the look and feel of your commercial flatware, the next question is always the same. Will it stay that way after months of dishwashing and daily handling? That answer depends more on stainless steel flatware grades than on pattern or finish. If you want a reliable restaurant flatware selection process, start here first, because the grade is what drives corrosion resistance, shine retention, and long-term flatware durability in hospitality tableware. 18/10 Flatware (Premium Standard) 18/10 flatware is the option many hotels and fine dining rooms default to when they want a polished, high-end look that holds up. It keeps its shine longer and handles frequent dishwashing well. If you often serve acidic foods, or if you want your hospitality tableware to look consistent across every service, 18/10 is usually the safest pick. It also feels more substantial, which many guests associate with quality. 18/8 Flatware (Balanced Choice) 18/8 is the practical middle ground. It performs well in busy dining rooms, looks clean on the table, and usually comes in a wider range of patterns. If you are managing a procurement budget but still want strong flatware durability, this is the grade many operators land on. You may see it listed as 304 stainless steel in supplier specs. 18/0 Flatware (High-Volume, Budget-Friendly) 18/0 flatware is chosen when loss and replacement are part of the reality, like cafeterias, schools, and quick service. It can be more prone to spotting and wear over time, so you plan for more frequent replacement. One practical advantage is that 18/0 is magnetic, which can help if your dish area uses magnetic retrievers. Flatware Weight Categories and Performance Flatware weight comes from metal thickness, not from stainless steel flatware grades. In commercial flatware, weight affects how often your team replaces bent forks and how well your set stands up to service. You can have 18/10 flatware that feels light, and 18/0 flatware that feels substantial. Here’s how to determine which flatware works best for your restaurant. Forged Flatware (Ultra-Premium, 70 to 90 grams) Forged flatware is made from a thicker piece of steel, so it feels solid and resists bending. In practice, this is what you choose when your dining room is selling an experience, and you want the guest to feel it in their hand. For instance, a fine dining restaurant serving steaks every night will notice fewer damaged pieces over time. The trade-off is that forged commercial flatware can feel heavy for some guests, especially in older audiences, and it sits at the top end of most procurement budgets. Extra Heavy Weight Flatware (Premium, 60 to 80 grams) Extra-heavy flatware gives you a premium feel without going fully forged. This is a common choice in hotel programs and upscale casual concepts because it balances flatware durability with cost control. For example, if your hotel has a breakfast outlet and a dinner outlet, an extra-heavy restaurant flatware selection helps both spaces feel consistent. It also holds up well in busy dishwashing cycles, which matters when volume is high. Heavy Weight Flatware (Standard, 55 to 70 grams) Heavyweight is the practical sweet spot for many operations. It feels substantial enough that guests read it as quality, but it is not so heavy that it feels bulky. A bistro with steady turnover, or a catering company that needs reliable hospitality tableware for repeated events, often lands here. If you want commercial flatware that performs well across most menus, this is usually the safest starting point. Medium Weight Flatware (Budget, 40 to 55 grams) Medium-weight flatware is built for cost and replacement flexibility. It can work in cafeterias, schools, and quick service settings where loss is expected and the priority is keeping inventory moving. The limitation shows up when food requires pressure. For instance, a medium-weight dinner knife and fork can bend more easily during steak service, which increases replacement needs over time. Forged vs Stamped Flatware Construction for Restaurants After you choose stainless steel flatware grades and flatware weight, the next decision in restaurant flatware selection is flatware construction. Construction is about how the piece is formed, and it affects bending, long-term wear, and how the pattern holds up through commercial dishwashing. For hotel procurement teams and catering operations, this is one of the easiest ways to predict flatware durability. Stamped Flatware Construction (Most Common in Commercial Flatware) Stamped flatware starts as a flat sheet of steel that is cut into shape, then pressed to form the handle design. It is fast to produce and easy to scale, which is why most commercial flatware programs use stamped patterns. For example, if you are buying hospitality tableware for a busy restaurant or a hotel buffet, stamped construction paired with heavyweight flatware can perform well in daily service. The key is to avoid thin economy sets. With the right weight and grade, stamped flatware can still feel professional and stay stable through repeated washing and handling. Forged Flatware Construction (Premium Build) Forged flatware is made by heating and shaping a thicker piece of steel, which creates a stronger utensil with more resistance to bending. The pattern is formed through the handle, not only pressed onto the surface. In practice, this matters when the flatware sees high pressure and constant use. For instance, a fine dining room using

Dinnerware Color Trends in Hospitality 2026: What’s Trending and Why It Matters

You walk into an intricately designed restaurant. Everything looks on point and beautiful. The lightning, the ambience, and the aroma of delicious food, all about the place, are inviting. But then you notice the plates. They stand out more than they should, and that, too, not in a good way. Dinnerware color today is no longer something you just put off to the last minute. It is part of the whole theme and customer experience. Apart from the very basic stark white today, we see a lot of warmer and earthier palettes. We have bold to pastel colors that look amazing on Insta, too. The color of the plate matters so much that you are judged before the first bite even lands in the mouth of the guest. Let’s talk about dinnerware color trends 2026. The Big Shift From Matching Sets For decades, hotels, restaurants, and event managers have played it safe with dinnerware colors. They chose one color, one size, and one finish. One matching set was used for all occasions, tables, and outlets, making it easy to source and replace. (Unfortunately, it was also quite easy to forget!) So today, we see hotels and restaurants moving towards creating intentional color schemes. They spend a lot of time and effort bringing color to the table without creating chaos. The plates, bowls, platters, and all other serving pieces are selected to work together visually. Like, they use ceramic tableware colors, and so the table looks better in photographs and Insta. It gives food a sense of depth that was initially lacking with flat, white sets. Pairing a warm neutral plate with a slightly darker bowl or a contrasting charger gives another dimension to the food. It makes things look well thought out and planned. These mixed and intentional palettes also increase the life of your dinnerware. Minor chips and glaze variations blend in better on earthy or jeweled-tones compared to white. Industry reports cite that the demand for mix-and-match tableware is rising, with an approximately 18% increase since 2024. Top Three Dinnerware Color Trends 2026 Dinnerware color trends in hospitality are designed based on certain elements. They are selected by keeping in view the space and how the businesses operate every day. Eyeing closely, you’ll see there are actually three broad categories of custom dinnerware colors that dominate the hospitality dinnerware design in 2026. Earthy Neutrals First off, you’ll see earthy-toned dinner plates as the top dinnerware color trend for 2026. There are different tones like clay, warm sand, terracotta, limestone, mushroom gray, and the like. These are loved because they solve a number of problems for event managers: Grounding: These tones do not compete with the main serving. Rather, they make them look rich and intentional. Hide Chips and Scratches:The earthy tones are very good at hiding minor scratches and chips (where white can be the least forgiving). Consistency:When used in high-volume restaurants, earthy dinnerware looks consistent and lasts without needing replacement for years. Depth: When different glazes are used in a combo, it feels like the spread is handcrafted. It shouts premium quality. Authenticity: Earthy dinnerware goes with all boutique restaurants, hotels, farm-to-table restaurants, resorts, and a host of other venues. That’s because it looks authentic. Deep Nature and Jewel Tones Many spaces layer their serving dishes in olive, forest greens, basal black, and stormy blue hues. But there’s a catch. Choosing the wrong shade or overly glossy finish can give off cheap vibes. The colors need to be aligned strategically. Usually, the best option is to go with neutral base plates like cream or bone white colors. Then, combine them with a deep green bowl or salad plate. Playing with contrasts makes it less overwhelming, yet the courses stand out visually. Jewel tones like emerald, deep navy, cobalt, burgundy, etc., too, are meticulously selected as intended accents. Here’s why: Drama: Deep nature tones bring drama to the table. They subtly elevate the perceived value as they trigger strong emotions. Luxury Feel: When used in the right combos, these make the food and setting feel more luxurious and well planned. Trending:Since the pandemic, hospitality dinnerware design is no longer minimalistic. Today, it has personality and depth. Rich:If you do not want to invest further in elaborate decor, just use deep ceramic tableware colors. These alone can make the ambience feel rich and confident. Soft Whites and Muted Washes Since we are talking colors and hues, you might be thinking, “Is white really out of style this year?” Short answer: No. But it definitely has evolved. Instead of using stark white, we now have options like eggshell, cream, and bone white. There are also pastel and other softly washed tones like blush, sage, pale blue, ash rose, and terracotta. Each piece makes the serving look appealing yet balanced. Neutral: These colors look neutral. They make the meal feel warm and intentional. Modern: The look gives off modern vibes. Photogenic: These tones also perform better on camera than white. Create a Difference: Muted washes and reactive glazes also make each serving look slightly different, which makes things visually interesting. It makes people feel that everything is consistent with the decor. Ideal For: This type of color family is best for contemporary cafés, concepts, lifestyle hotels, and wellness spaces Why Are These Color Trends Dominating 2026? In 2026, you can’t let your dinnerware’s color work on its own. To stand out in the competition, you need to respond to the way your guests want. You have to keep up with the market and how other event venues are performing. So, although dinnerware color is about appeal, behind these bold tones are the cultural shifts and psychological triggers. Let’s take a look at the ‘way’ behind these dominating color families. Let’s learn why they are leading the markets in 2026. Earthy and Natural Colors Natural energy, like warm sand, terracotta, and soft caramel, indicates authenticity and connection to nature. Today, diners expect sustainability as a core value. It’s no longer an option or add-on.

Brett Relocates to a New Office — A Warm Thank You for Joining Our Officewarming Ceremony

We’re excited to share an important milestone: Brett has officially relocated to our new address! To mark this new chapter, we recently hosted a housewarming ceremony at our new site, and it was truly an honor to celebrate together with so many wonderful people. We would like to extend our heartfelt thanks to all the friends, partners, and customers who took the time to visit, congratulate us, and share their kind wishes. Your support and encouragement mean a great deal to us—this celebration was made special because of your presence. This move represents more than just a change of location. It reflects Brett’s continued growth and our commitment to delivering even better service, stronger collaboration, and consistent quality for every project we support. With improved facilities and a refreshed working environment, we’re ready to serve you more efficiently and create even more value together. Once again, thank you for being part of this exciting moment. We look forward to welcoming you at our new location and continuing our journey together. https://youtu.be/3Fs2RDVjkyk?si=wpdJFY-LKPUemlIE Brett New address: Linrun Intelligent Valley, No. 1, R&D Route 5, SongShan Lake, Dongguan City,Guangdong Province Tel/WhatsApp: +86 13535413512 Email: ann@chinabrett.com

Sourcing Dinnerware From Custom Manufacturers vs Stock Suppliers: Complete Buyer’s Guide

Choosing between custom dinnerware manufacturers and stock dinnerware suppliers is one of the first big decisions in hospitality procurement, and it affects more than just what ends up on the table. For example, a hotel opening needs consistency across outlets, a restaurant wants a signature look guests remember, and a catering company needs reliable reorders when replacements come up. In that moment, many buyers go with what’s easiest to order, not what’s the smartest long-term. This guide breaks down both options clearly, so you can choose based on cost, timelines, durability, brand control, and reorder stability. Stock Catalogs vs Custom Manufacturing: How You’re Sourcing Dinnerware Stock dinnerware (ready-made catalogs) is the “pick it, order it, move on” route. You’re choosing from collections that already exist, made in bulk, and sold to lots of buyers at the same time. That’s why it feels easy. A restaurant that needs plates for next month’s opening can grab a clean white coupe plate from a large supplier, add a small logo on the rim, and be plating food within a couple of weeks. The trade-off is that the design is shared. If another venue down the road orders the same collection, your tables may start to look familiar. And if you prefer a specific glaze or design, you’re still at the mercy of the catalog. If it gets discontinued, your reorder becomes difficult to match. Custom dinnerware (OEM/ODM manufacturing) is a different kind of purchase. You’re not buying what exists. You’re commissioning what you want. In OEM, you bring the design (or a clear spec), and the manufacturer produces it to your requirements. In ODM, you bring the brief and constraints. For example, your specifications are matte ivory, wider rim, stack-safe, chip resistance, and a bowl that looks deeper than it is. The manufacturer develops options, then refines them with you. This is why boutique hotels prefer custom dinnerware options. They want a signature plate that matches the room palette, the menu style, and the photography. It takes longer because samples, molds, and production planning have to happen first, but the payoff is control and long-term repeatability. Practical Difference Stock is fast and budget-friendly upfront, but you’re working with someone else’s choices. Custom takes patience and more setup cost, but it turns dinnerware into a repeatable system you can reorder, expand, and keep consistent across years and locations. Cost Comparison: Upfront vs Long-Term In hospitality procurement, the dinnerware cost comes down to timing, replacement risk, and how stable your supply will be over the years. With stock dinnerware suppliers, the upfront cost is usually lower. You are buying a ready-made line, available immediately or with a short lead time, which helps a tight procurement budget. For a new opening, that speed can matter more than anything. The cost shows up later through breakage replacements, wear-related refreshes, and pattern changes. If a line is discontinued, the same dinner plate becomes a new purchase decision, sometimes across multiple vendors. With custom dinnerware manufacturers, the upfront cost is typically higher because you are funding development work (sampling and, in many cases, molds). Over time, the custom manufacturing cost can stabilize because reorders run from archived molds and glaze formulas. That reduces mismatch risk, limits reorder premiums, and often cuts admin time through a single supplier relationship, especially important in hotel procurement and multi-location operations. Factor Stock Dinnerware Suppliers Custom Dinnerware Manufacturers (OEM/ODM) Upfront Cost Lower to mid-range Mid-range to higher Long-term supplier pricing Can rise with discontinuation More stable on reorders Replacement Risk Higher (match issues) Lower (archived specs) Procurement Overhead Higher (more vendors) Lower (one partner) How Long Does Dinnerware Sourcing Take From Stock Suppliers vs Custom Manufacturers? For hospitality procurement, the dinnerware lead time is the make-or-break constraint. With stock dinnerware suppliers, timelines are usually simple, as many core items ship immediately, and if something is not on the shelf, the typical production timeline is about 1 to 2 weeks. If you add branding through logo printing on an existing line, plan for 2 to 3 weeks after artwork approval. Reorders tend to follow the same pattern, which is why stock feels predictable when you are opening fast or replacing pieces on short notice. With custom dinnerware manufacturers, the custom manufacturing timeline is longer because you are building the product before you buy it. Here’s a quick breakdown. Phase 1: Design Brief, Sampling, and Approvals This focuses on translating your concept into clear specifications, confirming the ceramic material and glaze finish, and reviewing prototype samples until the final design is approved. Phase 2: Mold Development and Fit Testing This is where the manufacturer builds or adapts molds and runs fit testing. This step can take anywhere from 1 to 4 weeks, depending on whether an existing mold can be modified or a new mold must be created and validated. Phase 3: Production, Quality Checks, and Packing This process covers raw material sourcing, firing cycles, inspection and consistency checks, and packing and logistics coordination, which commonly adds up to 7 to 10 weeks of production time. Which Option Delivers Better Quality: Stock Suppliers or Custom Manufacturers? Quality in hospitality is about dinnerware durability under commercial dishwashing, chip resistance in stacking, and whether reorders still match when you need replacements. That is where the difference between stock dinnerware suppliers and custom dinnerware manufacturers becomes clear. Stock Dinnerware Suppliers Stock lines are built for speed and availability, but quality and consistency depend heavily on the specific catalog tier you choose. Quality Variability by Tier Stock lines range widely. For example, high-end brands can deliver commercial-grade dinnerware with strong finishes and reliable food-safe dinnerware documentation. Mid-range catalogs are often acceptable for many restaurants, but performance can vary by collection. Budget imports are the most unpredictable; for instance, glaze hardness and rim strength can be inconsistent across batches. Durability in Service In commercial settings, premium stock may last years with manageable replacement rates, while mid-range and budget pieces tend to cycle out faster through chipping and glaze wear. The core

Beyond Dinner Plates: Complete Dinnerware Sets for Hotels and Catering

Commercial dinnerware sets are not just dinner plates and a few soup bowls. They’re the full table experience. Most hotels, caterers, and venues buy tableware in pieces, not as a whole dinnerware system, and that is where the table starts to look patched together. A wedding service might look perfect from across the room, then feel mismatched up close. A breakfast setup might run fine for a month, then replacements arrive in a different shade of white. That is why complete tableware solutions matter. This guide breaks down what professional venues really need, what to prioritize, and how to source custom ceramic dinnerware without creating procurement chaos. What Goes in a Complete Dinnerware Set? You’ll hear suppliers say “full set” all the time, but in hospitality, complete has a very specific meaning. It means that your dinnerware works as a complete system from plated dinners to breakfast service to banquet setups without forcing you to patch things together at the last minute. Plates: The Base That Sets the Look Your dinner plates (usually around 10 to 11 inches) are the first thing guests notice because they’re the main stage for every entree. That plate sets the tone for the whole table, so the shape, glaze, and color influence how premium the meal feels. Then you have salad or appetizer plates (around 8 to 9 inches). These are small, but they matter more than people expect. For instance, if your starter plate looks like it came from a different collection, the table starts looking mixed even if everything is “white.” And yes, even bread-and-butter plates (about 6 to 7 inches) make a difference. In five-star dining or formal events, these pieces signal that the setup was intentional, not just “good enough.” Here’s the part most teams learn the hard way: even when colors match, wrong proportions ruin the table. A salad plate that feels too small or too wide instantly looks off. Bowls: The Pieces You’ll Use Across Every Service Style Bowls are where a lot of venues unintentionally break the “complete set” concept. You’ll typically need soup bowls for formal dining, cereal or oatmeal bowls for breakfast, and deeper pasta bowls for flexible plating. These pieces carry a huge range of menus. Suppose your hotel runs breakfast daily and hosts plated weddings on weekends. If your bowls don’t match the rest of your dinnerware, your service feels inconsistent in photos and in person. A common mistake is buying bowls separately later. That’s when the scale is wrong, the glaze is slightly warmer or cooler, and the stack height feels different in the kitchen. Cups and Saucers: The Detail Guests Remember in Photos This is where ‘complete dinnerware sets’ separate premium venues from average ones. A coffee cup with a saucer instantly changes the feel of service. It looks polished. It photographs well. It even makes a simple coffee course feel higher-end. Then there are mugs, which are more casual, but they still need to match. For example, if your dinner plates feel luxurious and your mug looks like a random office cup, guests notice. They may not say it out loud, but it drops the impression. When cups share the same glaze tone, rim thickness, and handle style, the table feels like one idea instead of a mix of pieces. Serving Pieces: The Difference Between Nice and Professional Serving pieces are the part that venues forget during procurement until service starts. Serving platters, covered bowls, and small pieces like creamers or butter dishes may look optional, but they show up in buffets, VIP dining, and banquet service. Suppose your chef is sending out shared starters or your banquet team is doing bread service. If the serving pieces look mismatched, the whole table feels unfinished. And yes, serving pieces are the hardest to match later, because different suppliers use different clay bodies, glaze thickness, and shapes. Why Complete Dinnerware Sets Work Better A complete dinnerware system is not about having more items. It’s about avoiding gaps. You can have beautiful dinner plates, but if the bowls feel random or the cups don’t match, the table stops feeling premium. That’s why hotels, caterers, and event venues should treat dinnerware as a complete dinnerware system, not a one-time purchase of dinner plates. Why Fragmented Dinnerware Sourcing Doesn’t Work On paper, sourcing from multiple vendors sounds flexible. In practice, it’s where most venues lose control of the look, the quality, and the timeline. You might save a little upfront, then spend the rest of the season fixing small issues that keep piling up. Table Doesn’t Look Intentional Suppose your porcelain plates come from one supplier, your soup bowls come from another, and your serving platters come from a third. Even if everything is “white,” the tones rarely match perfectly. One looks warm, one looks cool, one has a different finish. Guests may not say it, but the table feels less premium. Inconsistent Quality Different suppliers use different standards. That’s why one batch feels solid, and the next scratches, chips, or fades faster than you expected. And once pieces break, replacement becomes annoying. Patterns change, finishes get updated, and suddenly your “matching” pieces don’t match anymore. That’s where commercial dinnerware sets turn into a recurring expense instead of a stable investment. When Procurement Turns Into Constant Follow-Up This is the part procurement teams don’t like. Multiple vendors mean multiple invoices, multiple delivery schedules, and more back-and-forth when one shipment arrives late or incomplete. It also adds pressure on staff because handling and stacking can vary between materials. How Professional Dinnerware Systems Work If you’ve ever tried to build a matching set from different suppliers, you already know the problem. The plates look close until you add the bowls. Then the cups. Then the serving pieces. That’s why professional venues lean toward an OEM dinnerware approach when they want consistency, control, and a clean reorder plan. OEM/ODM simply means you’re working with a partner who can design and manufacture your custom ceramic dinnerware as a

Top 10 Dinnerware Brands in Philippines Recommended

The Philippines has a vibrant homeware and tableware market, blending local brands with international names accessible through major retailers. Whether you’re setting up a new home, upgrading your dining table, or sourcing for foodservice and hospitality, choosing the right dinnerware brand matters for style, durability, and everyday comfort. In this guide, we’ve highlighted the top 10 dinnerware brands in Philippines, each with a reputable online presence and product reach across the country. These brands cover a wide spectrum—from affordable everyday sets to premium collections. Dinnerware Brands in Philippines Recommended 1. Melawares Philippines Website: https://melawares.com/ Melawares has been a mainstay in Filipino homes since the 1980s, known for its quality melamine and plastic dinnerware that combines durability with stylish design. Locals widely consider Melawares a go-to brand for everyday plates, bowls, and sets that withstand busy family use and frequent handling. Best known for: Stylish melamine dinnerware sets Durable, break-resistant tableware Affordable options for everyday dining 2. Nippon Ware Website: https://www.nipponware.com/ Established in 2000, Nippon Ware is one of the Philippines’ leading melamine tableware brands. Blending visual appeal with high functional performance, the brand’s products are widely available in department stores and supermarkets nationwide. Nippon Ware’s dinnerware is ideal for both home use and large gatherings where shatter-resistant pieces are important. Best known for: Melamine dinnerware with bold prints Party and family dinnerware sets Affordable, easy-to-clean pieces 3. Multiple Choice (PH) Website: https://www.multiplechoice.com.ph/ Multiple Choice Philippines serves as the local exclusive distributor for several international tableware collections. It offers porcelain and stoneware dinnerware under brands like Topchoice and Thomson Pottery, giving Filipino consumers access to a variety of design styles—from casual stoneware to refined porcelain. Best known for: Trendy porcelain dinnerware Stoneware collections with modern flair Dinner sets suited for home and casual restaurants 4. Casa Juan MNL Website: https://casajuan.ph/ Casa Juan MNL is a Filipino lifestyle brand that celebrates local culture, craftsmanship, and storytelling through thoughtfully designed home and dining pieces. Their ceramic plates and tableware often feature motifs inspired by Philippine heritage, tropical elements, and traditional patterns, making them popular among customers who appreciate artistic expression and cultural identity in everyday dining. Rather than mass-produced styles, Casa Juan MNL focuses on unique, design-driven collections that bring personality and warmth to the table—perfect for gifting, special occasions, or creating a statement dining setup. Best known for: Artistic and culturally inspired ceramic plates Locally designed tabletop collections Unique, gift-worthy dinnerware pieces 5. Silver Secrets Inc. Website: https://www.silversecretsinc.com/ Silver Secrets Inc. is a well-known Philippine retailer and distributor specializing in premium home and dining products, including fine chinaware, porcelain, and elegant tableware collections. The brand caters to customers seeking refined aesthetics, timeless designs, and high-quality materials suitable for both everyday dining and formal occasions. With a strong presence in major malls and online platforms, Silver Secrets has become a trusted name for those looking to elevate their table setting—whether for family gatherings, weddings, or sophisticated entertaining. Best known for: Premium porcelain and chinaware collections Elegant designs for formal and special occasions Gift-ready dinnerware and tabletop accessories 6. SM Home Website: https://smhome.ph/ SM Home is one of the Philippines’ most recognizable home and lifestyle retailers, operating under the SM Retail group. Known for its wide nationwide presence, SM Home offers an extensive selection of dinnerware, kitchenware, and home essentials designed for everyday Filipino households. Its dinnerware collections range from classic porcelain and ceramic sets to modern, trend-driven designs, making it a convenient one-stop destination for practical yet stylish tableware. Best known for: Wide range of ceramic and porcelain dinnerware Trend-inspired designs for modern homes Affordable and accessible nationwide availability 7. Slique Dinnerware Website: https://www.sunbeamslifestyle.com/pages/slique Slique dinnerware brings aesthetic value to everyday tables with marble-style melamine dinner sets. Its products are affordable, stylish, and resilient, appealing to buyers who want dinnerware that looks good but won’t break easily. Best known for: Marble-designed melamine dinnerware Complete dinner and salad plate sets Casual but stylish tableware 8. Rustan’s Dinnerware Selection Website: https://www.rustans.com/ While Rustan’s is not a dinnerware manufacturer itself, it’s one of the Philippines’ most prestigious luxury retailers carrying international dinnerware brands like Bordallo Pinheiro, Lenox, Oneida, and Tramontina. Rustan’s curated selections offer premium porcelain, bone china, and designer sets that elevate formal dining experiences. Best known for: Premium dinnerware from global brands Curated collections for elegant dining Porcelain, bone china, and designer sets 9. Crate & Barrel Philippines Website: https://crateandbarrel.com.ph/ A local extension of the global brand, Crate & Barrel Philippines offers contemporary dinnerware lines that blend modern design with everyday functionality. Its porcelain and stoneware pieces are a popular choice for trendy homes and gift registries. Best known for: Modern porcelain dinnerware Stylish everyday and entertaining collections Reliable retailer with online and in-store presence 10. Mandaue Foam Website: https://mandauefoam.ph/ Mandaue Foam is a well-established Filipino home and furniture brand that has expanded beyond mattresses and sofas to include a diverse line of home essentials, including dinnerware and tabletop accessories. With decades of experience in retail and manufacturing, the brand is trusted for offering functional, stylish, and budget-friendly products tailored to Filipino lifestyles. Their dinnerware collections focus on practicality, versatility, and contemporary aesthetics suitable for daily use. Best known for: Budget-friendly ceramic and tableware collections Functional designs for everyday dining Strong nationwide retail network Tips for Choosing Dinnerware in the Philippines When selecting dinnerware brands in the Philippines, consider these key factors: 1. Daily Use vs Special Occasions Basic melamine sets like Nippon Ware and Melawares are ideal for everyday meals—especially in busy households or outdoor gatherings. Premium porcelain and bone china (sourced through Rustan’s or Crate & Barrel) are better for formal settings. 2. Material Matters Melamine and plastic dinnerware are durable and shatter-resistant, great for parties and children. Porcelain and stoneware provide a more refined dining experience with elegant aesthetics. 3. Design & Functionality Choose patterns and colors that match your dining space and lifestyle. Contemporary brands (like Slique and Crate & Barrel) offer trendy designs, while others prioritize traditional form and function. 4. Retail & Sourcing Options Many international and local dinnerware brands in the Philippines are distributed through department stores and online platforms—so browsing options and prices across multiple

Five-Star Hotel Procurement Guide: The Complete One-Stop Solution Approach

Five-star hotel procurement is rarely about buying products. It is about coordinating dozens of decisions, timelines, and standards while protecting a luxury brand from inconsistency. From dining to guestrooms to back-of-house operations, every sourcing choice carries weight. If you have ever managed multiple suppliers while trying to keep things aligned, this hotel procurement guide is designed to show a better way forward through a consolidated, one-stop procurement approach. The Fragmentation Problem in Luxury Hotel Procurement Five-star hotels operate at a level where details are not optional. Guests may never see the procurement process, but they feel its results everywhere. The weight of the cutlery, the comfort of the bedding, and the quality of the gym equipment shape the guest experience. The challenge is that most luxury properties still source these elements separately, across many vendors, each with different standards and timelines. Procurement teams commonly manage dinnerware through one supplier, kitchen equipment through another, amenities through a third, and bedding, barware, and fitness equipment through several more. On paper, it feels simple enough. But once you’re in the middle of service, the small issues start piling up. As the operation grows, those little gaps take more time, more attention, and more work than anyone expects. Where fragmentation creates problems: Different suppliers working to their own standards, which leads to small inconsistencies Hours spent chasing timelines, approvals, and deliveries across a long list of vendors One missed production or shipping window throws the entire schedule off balance Materials, finishes, or colors that don’t quite match once everything is in the room Extra admin work from managing multiple contracts, invoices, and payment cycles These problems soon become a strategic issue. For five-star properties evaluated on hundreds of service and facility criteria, inconsistency is costly. Fragmented procurement makes it harder to maintain a cohesive luxury standard, especially during openings, renovations, or multi-property rollouts. A consolidated approach brings one point of coordination, one quality standard, and one procurement strategy aligned to the hotel’s brand vision. What Does Five-Star Hotel Procurement Cover? At first glance, five-star hotel procurement can look like a long list of items to source and tick off. You soon realize it’s less about buying products and more about making sure everything feels connected. When one piece feels slightly off, it affects the guest experience. That’s why luxury hotels don’t think in isolated categories. They think about everything that shows up together. A simple way to break down five-star hotel procurement is by looking at the three areas guests experience as one continuous story. Dining and Beverage One of the first moments guests interact with the hotel is at the table. Plates, glassware, cutlery, and barware set the tone. If the dinnerware feels refined but the glassware doesn’t match, the table looks poor. In a five-star environment, weight, finish, and durability need to feel intentional across fine dining, room service, and even the lobby bar. In fact, hospitality advisors point out that even a single subpar item, such as chipped plates or worn barware, can break the illusion of luxury and subtly undermine the overall guest experience. Guest Experience Guests don’t just look at linens, bedding, towels, and in-room amenities; they also use them every day, which influences guest experience. If the bed feels premium but the bathroom accessories feel generic, the experience loses momentum. Hotels that treat guest-facing items as part of one design language usually deliver a stay that feels more considered and complete. Operations and Functionality Guests may never see kitchen equipment, fitness machines, or housekeeping tools, but they absolutely feel the outcome. Reliable equipment keeps service smooth. Quality back-of-house choices prevent delays. When operations fall short, it doesn’t feel like a product issue but a service issue. Why Alignment Makes the Difference Hotels that work with fewer, more coordinated partners tend to deliver a more cohesive luxury experience. Industry observations also show that hotels sourcing through a single, coordinated supplier tend to achieve noticeably higher guest satisfaction around cohesive luxury aesthetics than those using a fragmented, multi-vendor approach. When procurement is aligned under a clear strategy through consolidated hotel sourcing, the quality feels deliberate. That’s why properties with tighter procurement alignment often hear the same feedback again and again: everything just felt well thought out. Why Multi-Vendor Procurement Breaks Down in Five-Star Hotels At first, working with multiple suppliers can feel flexible. You get to pick “the best” in each category. But once procurement moves from planning into execution, that flexibility starts creating extra work no one planned for. In five-star hotel procurement, the cost of fragmentation rarely shows up on a quote sheet. It shows up in time, coordination, and quality control. The Day-to-Day Load on Procurement Teams Once you’re dealing with ten different suppliers, your day fills up fast. That’s ten conversations to manage, ten delivery dates to watch, and ten sets of follow-ups sitting in your inbox And don’t underestimate the time that goes into emails, confirming details, double-checking specs, and clearing up small misunderstandings. None of that improves the guest experience, but it takes up hours every week. Where Timelines Slip Where do things slow down? One supplier confirms delivery. Another comes back asking for a spec adjustment. A third pushes their date back. Before you know it, dinnerware shows up before the kitchen is ready, or guestroom items arrive without final sign-off. Teams end up making last-minute calls just to keep things moving, right when the project should be settling into place. When Quality Control Lands on Your Desk With several vendors in play, there’s no single reference point for finishes, materials, or durability. Procurement teams end up comparing samples, pointing out mismatches, and asking for revisions. Even small differences, slightly different whites or finishes that don’t quite line up, start to stand out in a five-star environment where consistency matters. Administrative Load Different suppliers also mean different invoices, payment terms, and billing cycles. Finance teams spend extra time approving, tracking, and reconciling across categories. What looks manageable early on becomes harder to