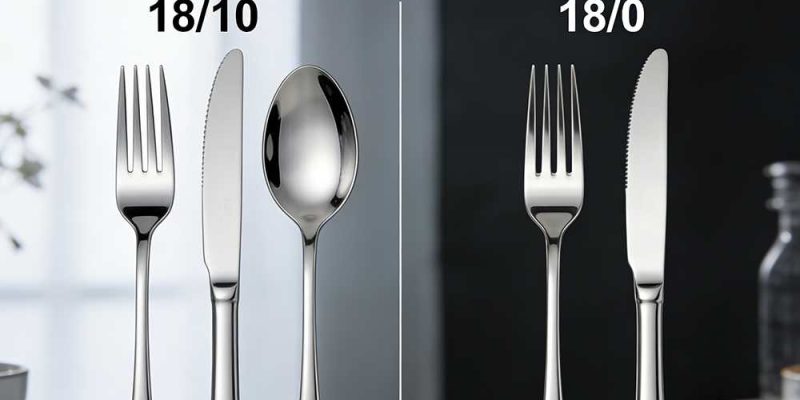

Stainless steel flatware comes in different quality levels, and the numbers on the box, like 18/10 or 18/0, actually tell you what you’re buying. Those grades refer to the mix of chromium and nickel inside the steel, and that mix affects flatware durability, shine, and how long it holds up in daily service.

If you’re comparing 18/10 flatware vs 18/0, the decision usually comes down to one thing: do you want a lower upfront price, or a longer flatware lifespan with fewer replacement cycles?

In this guide, we’ll break down stainless steel grades, performance, and a simple cost comparison so your hospitality procurement choice feels easy.

What’s the Difference Between 18/10 Flatware vs 18/0?

When you’re buying flatware for a restaurant, hotel, or catering setup, these stainless steel grades tell you what the steel is made of, and that directly affects how your flatware looks after months of dishwashing, heavy service, and constant handling.

So if you’re stuck choosing between 18/10 vs 18/0 flatware, this section breaks it down.

18/10 Stainless Steel Flatware

18/10 flatware is stainless steel flatware made with 18% chromium and 10% nickel. That nickel is the reason it’s considered the premium option in hospitality.

It helps the flatware stay shinier, resist rust spots, and hold up better through heavy dishwashing and daily service use.

This is the type of flatware you pick when you want your cutlery to still look sharp after a long season of service, not just on day one.

18/0 Stainless Steel Flatware

18/0 flatware is stainless steel flatware made with 18% chromium and 0% nickel. It’s usually the budget-friendly option because it skips the nickel, which keeps the cost down.

The trade-off is that it can lose its shine faster over time and may show more spotting or surface wear in busy commercial kitchens.

How 18/10 and 18/0 Stainless Steel Grades Are Named

The format for stainless steel grades is simple: X/Y. The first number is the chromium percentage, and the second number is the nickel percentage.

So when you see 18/10, that means the flatware contains around 18% chromium and 10% nickel.

And 18/0 means around 18% chromium and 0% nickel.

Now you might ask, why does this matter? Because those two metals decide how your flatware holds up once it’s been through hundreds of wash cycles, gets tossed into bus tubs, and gets handled by multiple staff members in one night.

What Chromium Does (The “18” Part)

Chromium is what gives stainless steel its basic rust resistance. It forms a protective layer on the surface, so the steel doesn’t break down easily when it’s exposed to water, heat, and daily washing.

That’s why both 18/10 and 18/0 can still qualify as “stainless,” because both rely on chromium for that base protection. So even if you choose 18/0 flatware, you’re not choosing something low-quality by default. You’re choosing a grade that’s built for value, with fewer extras.

What Nickel Changes (The “10” vs “0” Part)

Nickel helps flatware keep that cleaner shine longer, and it improves resistance to spotting, surface wear, and corrosion marks that can show up when cutlery goes through heavy service routines.

It also changes the feel in the hand. If you’ve ever picked up cutlery and thought, “Yeah, this feels premium,” nickel is usually part of that story. The reason 18/10 costs more is simple: nickel isn’t cheap, and adding it changes both performance and price.

Why You’ll Also See 18/8 (And Why It Confuses Buyers)

If you’ve been shopping for stainless steel grades, you’ve probably noticed 18/8 sitting right beside 18/10.

Here’s the short version: in most commercial cases, 18/8 and 18/10 perform very similarly, and the difference is rarely something you’ll feel during service.

A lot of suppliers buy steel that falls within a range, then label it based on what sells best. Some call it 18/10. Some call it 18/8. The British Stainless Steel Association even notes that 18/10 is sometimes used as an alternative label to 18/8, and in practice, it can be more marketing than a true upgrade. So treat them as the same tier and compare quality, pros, and cons instead.

Take a look at the pros and cons of stainless steel flatware grades.

Grade | Pros | Cons |

18/10 Stainless Steel Flatware | l Strong rust and corrosion resistance in commercial dishwashing l Holds its shine and polish for longer l Better resistance to staining, spotting, and pitting l Feels more premium in weight and finish l Long-term durability makes it ideal for daily service | l Not magnetic (can matter for some recovery systems) l Not always necessary for casual or short-term setups l Higher upfront cost compared to 18/0 |

18/0 Stainless Steel Flatware | l Lower cost upfront (budget-friendly for bulk buying) l Magnetic (easier to recover in dishwashing/trash systems) l Works fine for casual service and lower-expectation settings l Good corrosion resistance for the price (still stainless steel) | l More likely to lose shine faster over time l Can show spotting, staining, or dulling sooner l Less resistant to harsh washing conditions and acidic residue l May need more frequent replacement in high-volume venues |

Performance Comparison: How Stainless Steel Grades Differ in Practice

Both stainless steel grades look great when they’re brand new. The difference shows up after weeks of dishwashing, busy shifts, and constant contact with food, water, and heat.

If you’re choosing based on flatware durability and flatware lifespan, this is the part that makes the decision clear.

Durability and Lifespan

In a restaurant, hotel, or catering business, flatware gets tossed in bus tubs, soaked, washed on high heat, and used the same day. That’s where 18/10 stainless steel usually performs better.

It stays cleaner and brighter longer and holds up better when your menu includes acidic foods like lemon, vinegar, or tomato sauce. This is why flatware lifespan can look completely different between stainless steel grades, even when both sets start out looking the same.

18/0 flatware still works, but in heavy service, it can start looking dull or spotty sooner, especially with hot dishwashing, hard water, or wet storage.

The Visual Aging Story

At the start, both stainless steel grades look great. You unbox them, they shine, and service feels clean and polished.

But after months of nonstop washing and handling, you’ll usually see 18/0 flatware start to fade first, with little spots, dull patches, or that “it’s clean but still doesn’t look clean” problem.

By year three, some teams are already polishing 18/0 more just to keep it presentable. 18/10 flatware tends to stay brighter for longer, so you’re not fighting the look every weekend.

Staining Resistance

Let’s say your restaurant serves a lot of salads, citrus marinades, or vinaigrettes. Totally normal menu, but it’s rough on flatware. The forks sit in a wet tub, then go straight into dishwashing, sometimes with leftover acidic residue still on them.

With 18/0, that’s when spotting and surface discoloration can show up faster, and your staff ends up scrubbing harder to fix it.

With 18/10 stainless steel, you usually get less staining, less polishing, and fewer “why does this look old already?” moments.

Magnetic Properties and Operational Implications

This sounds like a small detail, but in some kitchens it matters. 18/0 flatware is magnetic, so if you use magnetic flatware retrievers near trash or dish areas, you can save a lot of pieces from getting thrown out. That can genuinely help with replacement costs in high-volume service.

18/10 flatware is usually non-magnetic, so you won’t get that advantage. Still, most operators don’t choose a grade based on magnetism alone; it’s just a bonus if your setup already supports it.

Cost Analysis: Upfront Price vs Total Cost Over Time

This is where the decision gets clearer. Yes, 18/0 flatware looks like the smart deal on day one because the upfront bill is lower.

But once you factor in ongoing replacements, extra polishing, and the fact that budget-grade flatware starts looking worn faster in busy kitchens, the long-term spend starts creeping up.

18/10 stainless steel costs more at purchase, but it usually stays in service longer with fewer “we need to replace half the set” moments.

So if you’re planning to run your operation for 5+ years, the total cost of ownership comparison is where 18/10 starts making more financial sense.

Cost Category (100-seat restaurant / 1,250 pieces) | 18/10 Stainless Steel Flatware | 18/0 Stainless Steel Flatware |

Upfront cost (Year 0) | Higher ($12 to $18 per piece range) | Lower ($5 to $8 per piece range) |

Initial investment example | $18,000 | $8,000 |

Annual replacement trend | Low (mainly loss) | Higher (loss + visible wear) |

Maintenance effort | Minimal polishing | More polishing |

5-year total picture | Typically stays presentable with small top-ups | Usually needs heavier replacement cycles |

10-year total picture | Long service life with steady costs | Multiple refreshes/replacements add up |

Crossover point | Breaks even around year 4 and then costs less overall | Cheaper early, more costly later |

Best fit | Long-term operations, premium brands | Short-term use, high-loss environments |

Quick Takeaway

If you’re doing a flatware cost comparison for long-term hospitality procurement, 18/10 is usually the “pay once, stress less” option. If you’re managing short-term budget pressure, 18/0 can work, but you’ll want to plan for faster turnover.

18/10 vs 18/0 Flatware: Which One Fits Your Service Style?

If you’re comparing 18/10 flatware vs 18/0, this section helps you match stainless steel grades to your operation, based on flatware durability, expected wear, and flatware lifespan.

When to Choose 18/10 Stainless Steel Flatware

If your tables are meant to feel polished every day, 18/10 stainless steel is usually the safer bet. For a lot of teams, it ends up being the better cost comparison choice once replacements and upkeep start adding up.

Choose 18/10 flatware when:

- You run fine dining, upscale casual, or luxury hotel service

- Your flatware runs through commercial dishwashers nonstop

- Your menu includes acidic items (citrus, vinegar, tomato sauces)

- You want long-term consistency without chasing replacements

- You don’t want polishing to become a weekly staff task

When to Choose 18/0 Stainless Steel Flatware

18/0 flatware is built for practicality. It keeps your upfront spend lower, which matters when you’re buying in bulk or when losses are part of the job.

You can still run great service with it, but you’re trading some shine and long-term finish for budget control and easier replacement planning in hospitality procurement.

Choose 18/0 flatware when:

- You run fast-casual, cafeterias, high-turnover dining, or catering kits

- Flatware loss is constant (events, trash throwouts, off-site service)

- You already replace pieces regularly

- Your service is quick, and you’re not selling a luxury “table feel.”

- You use magnetic recovery systems and want that advantage

Decision Matrix

If you’re stuck, don’t overthink it. Answer these, and your decision gets clearer.

Ask yourself:

- How long do you want this set to last before it looks old? (flatware lifespan matters here)

- How harsh is your dishwashing setup? (heat, water hardness, volume)

- What are you selling at the table? Value dining or premium dining?

- Are you okay replacing more pieces every year to keep it looking clean?

If you’re building a restaurant or hotel experience that’s meant to feel polished every day, 18/10 flatware vs. 18/0 usually ends with 18/10 being the better long-term call for durability and consistency.

Maintenance and Lifespan Extension Strategies

Good flatware care is what protects your flatware’s lifespan, no matter which stainless steel grades you buy. If you’re running a busy restaurant or hotel, the biggest damage usually happens between the table and the dishwasher.

Food dries, moisture sits too long, and suddenly your team is scrubbing and polishing just to keep service looking clean. 18/10 stainless steel is more forgiving, while 18/0 flatware needs a little more attention if you want it to stay presentable.

Here are some tips for flatware lifespan extension.

- Clear food off fast, especially anything acidic like lemon or tomato

- Quick soak 5 to 10 minutes, then wash right away

- Do not leave flatware sitting wet in bus tubs

- Use rinse aid if you see spotting (helps 18/0 the most)

- Keep dishwasher temps reasonable, not extreme

- Store fully dry with airflow, not stacked tightly

- Polish 18/0 as needed, but avoid aggressive scrubbing

- Separate forks, spoons, and knives so edges don’t rub

Wrapping Up

If you’re sourcing flatware for a restaurant, hotel, or catering program, take a look at Brett’s premium stainless steel flatware options. Brett supports hospitality teams with consistent quality, bulk ordering, and long-term reordering support so your cutlery stays matched as service scales. Reach out to Brett today to request specs, pricing, or samples for your next flatware order.